| Specifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Type |

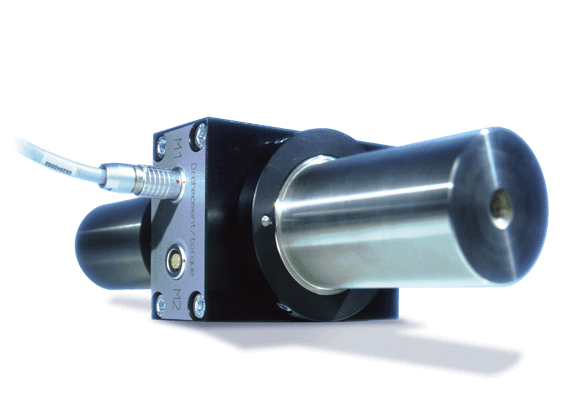

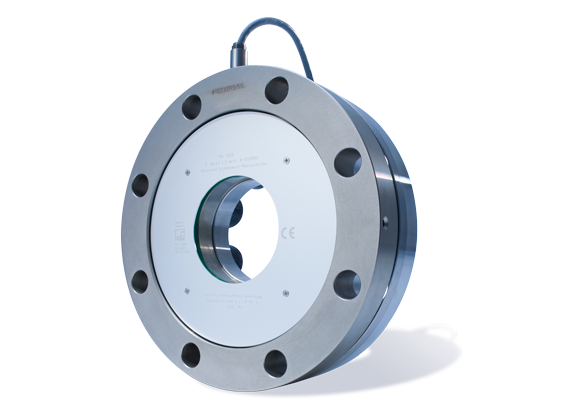

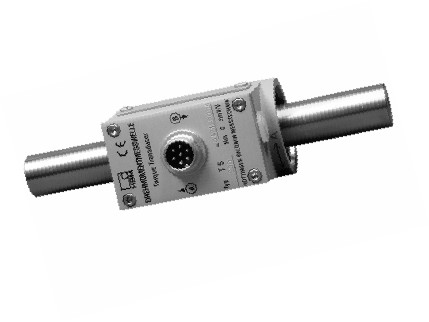

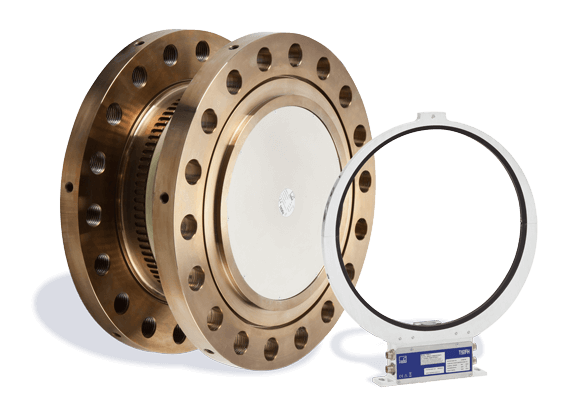

TB2 |

|

|

|

| Accuracy class |

0.03 |

|

|

|

| Nominal (rated) torque Mnom |

N×m |

100 |

200 |

500 |

|

|

|

|

|

|

|

|

| kN×m |

|

|

|

1 |

2 |

3 |

5 |

10 |

|

|

|

| Nominal (rated) sensitivity (spread between torque = zero and nominal (rated) torque) |

mV/V |

1 |

|

|

|

| Sensitivity tolerance (deviation of the actual output quantity at Mnom from the nominal (rated) sensitivity) |

% |

<土0.1 |

|

|

|

Temperature effect per 10K in the nominal (rated) tempera- ture range

on the output signal, related to the actual value

on the zero signal, related to the nominal (rated) sensitivity |

%

% |

<土0.03

<土0.02 |

|

|

|

Linearity deviation, including hysteresis

relative to nominal (rated) sensitivity

the relative standard deviation of repeatability

according to DIN 1319, relative to the variation of the output signal |

%

% |

<土0.03

<土0.01 |

|

|

|

Input resistance at reference temperature Output resistance at reference temperature Reference excitation voltage

Operating range of excitation voltage |

Ω Ω V V |

1550土100

900 ¼ 1500

5

2.5 ¼ 12 |

|

|

|

| Emission in accordance with (EN61326-1, Table 4) RFI field strength |

|

Class B |

|

|

|

Interference immunity (EN61326-1, Table A.1) Electromagnetic field (AM)

Magnetic field

Electrostatic discharge (ESD) Contact discharge

Air discharge

Burst (rapid transients) Surge (impulse voltages) Cable based interferences |

V/m A/m

kV kV kV kV V |

10

100

4

8

2

1

10 |

|

|

|

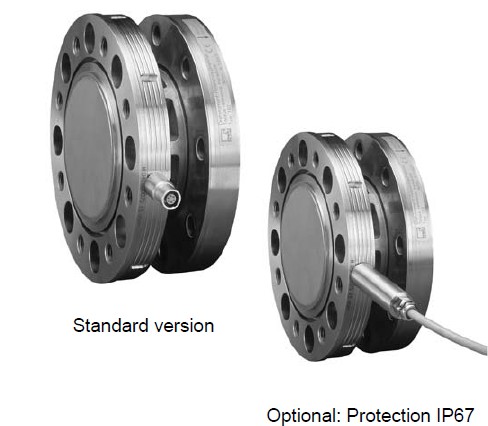

| Degree of protection per EN 60,529 |

- |

IP54, optional IP67 |

|

|

|

Nominal (rated) temperature range

Operating temperature range Storage temperature range |

°C

°C

°C |

+10 ¼ +60

−10 ¼ +80

−50 ¼ +85 |

|

|

|

Mechanical shock, test severity level per DIN IEC 68; Part 227; IEC 682271987

Number Duration

Acceleration (half sine) |

n ms m/s2 |

1000

3

650 |

|

|

|

Vibrational stress, test severity level according to DIN IEC 68; Part 26; IEC 68261982

Frequency range Duration

Acceleration (amplitude) |

Hz h

m/s2 |

5 ¼ 65

1.5

50 |

|

|

|

Load limits1)

Limit torque, related to Mnom Breaking torque, related to Mnom Longitudinal limit force

Lateral limit force Limit bending moment

Oscillation width per DIN 50100 (peaktopeak) |

%

%

kN kN N×m N×m |

|

|

|

|

200

>400 |

160

>320 |

|

|

|

5

1

50

200 |

10

2

100

400 |

16

4

200

1000 |

19

5

220

2000 |

39

9

560

4000 |

42

10

600

4800 |

80

12

800

8000 |

120

18

1200

16000 |

|

|

|

| 1) Each type of irregular stress (bending moment, lateral or longitudinal force, exceeding nominal (rated) torque) can only be permitted up to its specified static load limit, provided none of the others can occur at the same time. If this condition is not met, the limit values must be reduced. If 30% of the bending limit moment and lateral limit force occur at the same time, only 40% of the longitudinal limit force is permis- sible and the nominal (rated) torque must not be exceeded. The permissible bending moments, longitudinal forces and lateral forces can affect the measurement result by approx. 0.2% of the nominal (rated) torque. |

| Specifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Mechanical values |

| Nominal (rated) torque Mnom |

N×m |

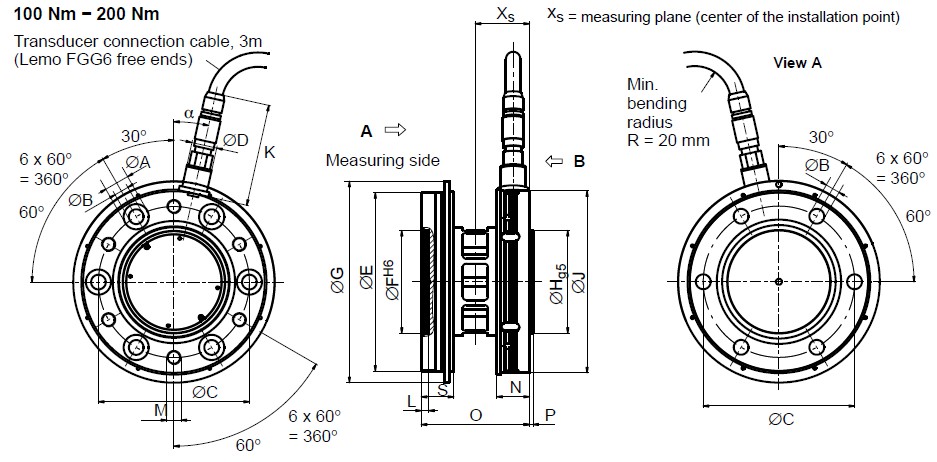

100 |

200 |

500 |

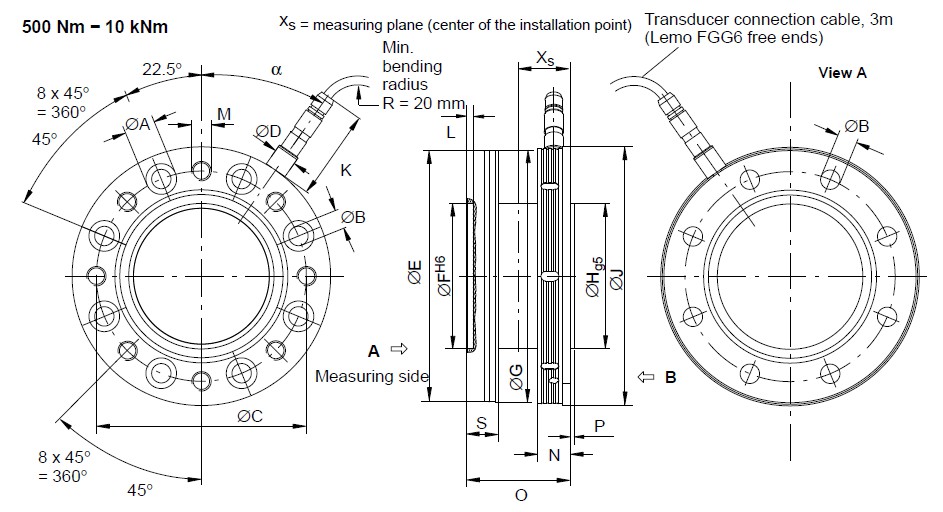

|

|

|

|

|

| kN×m |

|

|

|

1 |

2 |

3 |

5 |

10 |

| Torsional stiffness |

kN×m/rad |

230 |

270 |

540 |

900 |

2300 |

2600 |

4600 |

7900 |

| Torsion angle at Mnom |

Degree |

0.048 |

0.043 |

0.055 |

0.066 |

0.049 |

0.066 |

0.06 |

0.07 |

| Stiffness in axial direction, approx. |

kN/mm |

420 |

800 |

900 |

970 |

1000 |

1100 |

950 |

1600 |

| Stiffness in radial direction, approx. |

kN/mm |

130 |

290 |

700 |

840 |

1400 |

1600 |

1400 |

2500 |

| Stiffness during the bending moment around a radial axis |

N×m/rad |

66 |

120 |

165 |

170 |

380 |

390 |

550 |

1240 |

| Maximum deflection at longitudinal force limit |

mm |

0.02 |

<0.03 |

<0.05 |

<0.1 |

| Additional max. radial run-out deviation at lateral limit force |

mm |

<0.01 |

| Additional plane/parallel deviation at bending moment limit |

mm |

<0.03 |

<0.04 |

<0.06 |

<0.1 |

| Mass moment of inertia (without taking flange bolts into account) of rotor Iv (around the longitudinal axis) |

kg×m2×10−3 |

1.6 |

2.6 |

5.9 |

19.2 |

37 |

97 |

| Proportional mass moment of inertia (measuring side) |

% |

56 |

55 |

52 |

50 |

| Position of SG level (as distance to level of adap- tion surface of flange with external centering) |

% of total length |

50 |

| Weight, approx. (excl. cable) |

kg |

0.7 |

1.7 |

2.4 |

4.9 |

8.3 |

14.6 |

| Weight, IP67 version, approx. (incl. cable) |

kg |

0.9 |

1.9 |

2.6 |

5.1 |

8.5 |

14.8 |

| Supplementary data as per DIN 51309 or EA 10/14 |

Class as per DIN 51309

Rel. zero error (zero signal return) |

% |

0.05

<土0.008 (typical <0.003) |

Relative reproducibility and repeatability errors (0.2 Mnom to Mnom) for:

a constant mounting position a changing mounting position |

%

% |

<0.02 (typical <0.01)

<0.03 (typical <0.02) |

| Relative hysteresis error (0.2 Mnom to Mnom) |

% |

<0.06 (typical <0.03) |

| Scope of supply: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TB2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Transducer connection cable, 3m, (Lemo® FGG6-free ends) Test certificate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Mounting instructions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Option: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Degree of protection IP67 per EN 60529 Order No.: D-TB2/IP67 |

|

|

| Accessories: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Connecting plug MS 3106PEMV, mounted on cable Order No.: D-MS/MONT |

|

| 15 pin D-plug, mounted on cable Order No.: D-15D/MONT DKD calibration certificate to DIN 51309 or EA10/14 |

售前咨询

售前咨询