| Specifications |

|

|

|

|

|

|

|

|

|

|

|

|

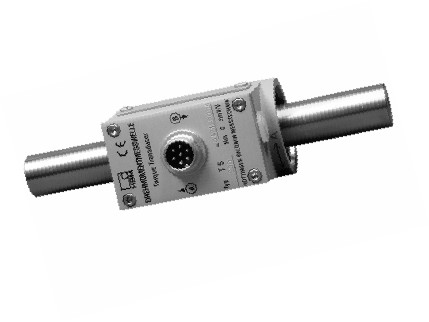

| Type |

T4A/T4WA-S3 |

|

| Accuracy class |

0.2 |

0.1 |

|

| Torque measuring system |

| Nominal (rated) torque MN |

N×m |

5 |

10 |

20 |

50 |

100 |

200 |

500 |

1000 |

| Nominal (rated) sensitivity (nominal (rated) output signal at |

mV/V |

2 |

| nominal (rated) torque) |

% |

<土 0.2 |

| Sensitivity tolerance |

|

|

Temperature effect per 10K in the nominal (rated) temperature range

on the output signal (related to actual value) |

%

% |

< 土0.1

< 土0.1 |

| on the zero signal (related to nominal (rated) sensitivity) |

| Non-linearity including hysteresis |

% |

0.2 |

0.1 |

| (related to nominal (rated) sensitivity) |

| Relative standard deviation of reproducibility per DIN |

|

< 土0.05 |

| 1319 (related to variation of the output signal) |

% |

| Input resistance at reference temperature (T4A) |

ohm |

350土 1.8 |

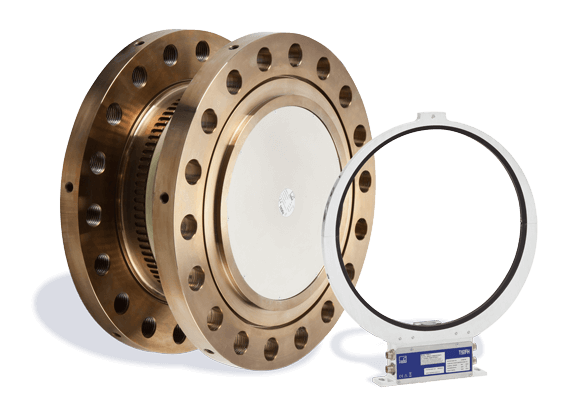

| T4WA−S3 torque measuring system |

ohm |

420土40 |

| Output resistance at reference temperature |

ohm |

350土 1.5 |

| Maximum permissible excitation voltage |

V |

20 |

| Nominal (rated) range of the excitation voltage |

V |

0.5 ... 12 |

| Reference temperature |

oC |

23 |

| Nominal (rated) temperature range |

oC |

+10...+60 |

| Operating temperature range |

oC |

-10...+60 |

| Storage temperature range |

oC |

-50...+70 |

| Torsional stiffness approx. |

kN×m/rad |

0.29 |

0.61 |

1.08 |

2.42 |

5.57 |

7.53 |

27.3 |

65 |

| Torsion angle at nominal (rated) torque, approx. |

degrees |

1 |

0.9 |

1.1 |

1.1 |

1.0 |

1.5 |

1.0 |

0.9 |

| Mass moment of inertia |

gm2 |

0.04 |

0.04 |

0.04 |

0.04 |

0.04 |

0.04 |

0.28 |

0.44 |

| Maximum permissible rotational speed |

min−1 |

4000 |

| Brush service life, approx. |

revs. |

3 x 108 |

6 x 108 |

| Mechanical values (related to nominal (rated) torque) |

% |

|

| Static limit load |

150 |

125 |

150 |

| Static breaking load |

% |

300 |

200 |

300 |

| Lateral limit force on shaft 1) |

N |

5 |

10 |

20 |

50 |

80 |

125 |

235 |

370 |

| Longitudinal limit force on shaft 1) |

kN |

0.35 |

0.7 |

2.0 |

3.5 |

5.5 |

8.8 |

16.4 |

25.9 |

| Limit bending moment on shaft 1) |

N×m |

0.75 |

1.5 |

3 |

6 |

11 |

23 |

57 |

114 |

| Oscillation width per DIN 50100 (rel. to nominal (rated) torque) |

% |

70 (peak-to-peak)

+MN and -MN |

| Upper and lower limits |

Impact resistance, test severity level per DIN IEC68, Part 2-27; IEC 68-2-27-1987 Number

Duration

Acceleration (half sine)

Vibration in 3 directions according to DIN IEC 68; Part 26; IEC 682271987

Frequency range Duration

Acceleration (amplitude)

Weight, approx.

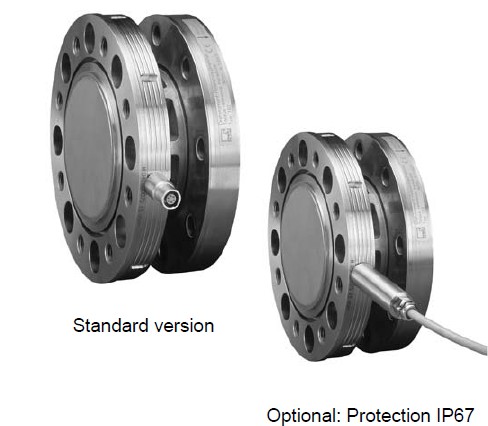

Degree of protection per DIN IEC 60529 |

ms m/s2

Hz h

m/s2

kg |

0.4 |

1000

3

500

5...65

1.5

50

IP50 |

1.8 |

2.4 |

| Rotational speed/angle of rotation measuring system (T4WA only, version no longer available) |

| Angle of rotation transducer with two output signals |

mm |

each 90 pulses per revolution, offset by 1/4 period |

| Tolerance of the slot width |

土0.05 |

| Average optical diameter |

|

|

| T4WA-S3/5 N×m ... 200 N×m |

mm |

approx. 31 |

| T4WA-S3/500 N×m and 1 kN×m |

mm |

approx. 53 |

| Output voltage (square-wave) |

V |

5, TTL level |

| Supply voltage |

VDC |

4.8...5.2 |

| Max. current consumption |

mA |

50 |

售前咨询

售前咨询