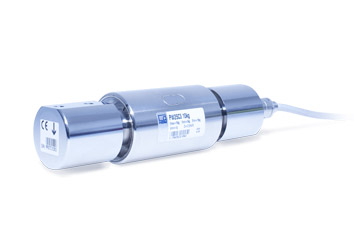

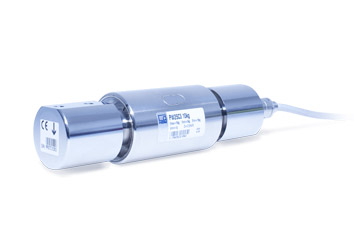

FIT7A用于自动检重秤,分选包装设备的数字称重传感器

- 所属分类:德国HBM称重传感器

- 产品标签:德国称重传感器

- 设备特点:用于自动检重秤、结实可靠、智能

646

- 特别说明:产品图片以及参数跟实际产品略有差异。

- 采购说明:一切规格按照客户实际情况或考察后下单采购,支持非标定制。

- 库存配送:有货,全国送货保障!

- 温馨提示:本产品一经下单采购,非质量问题不支持退货!如产品质量问题,可三个月内免费退换货!

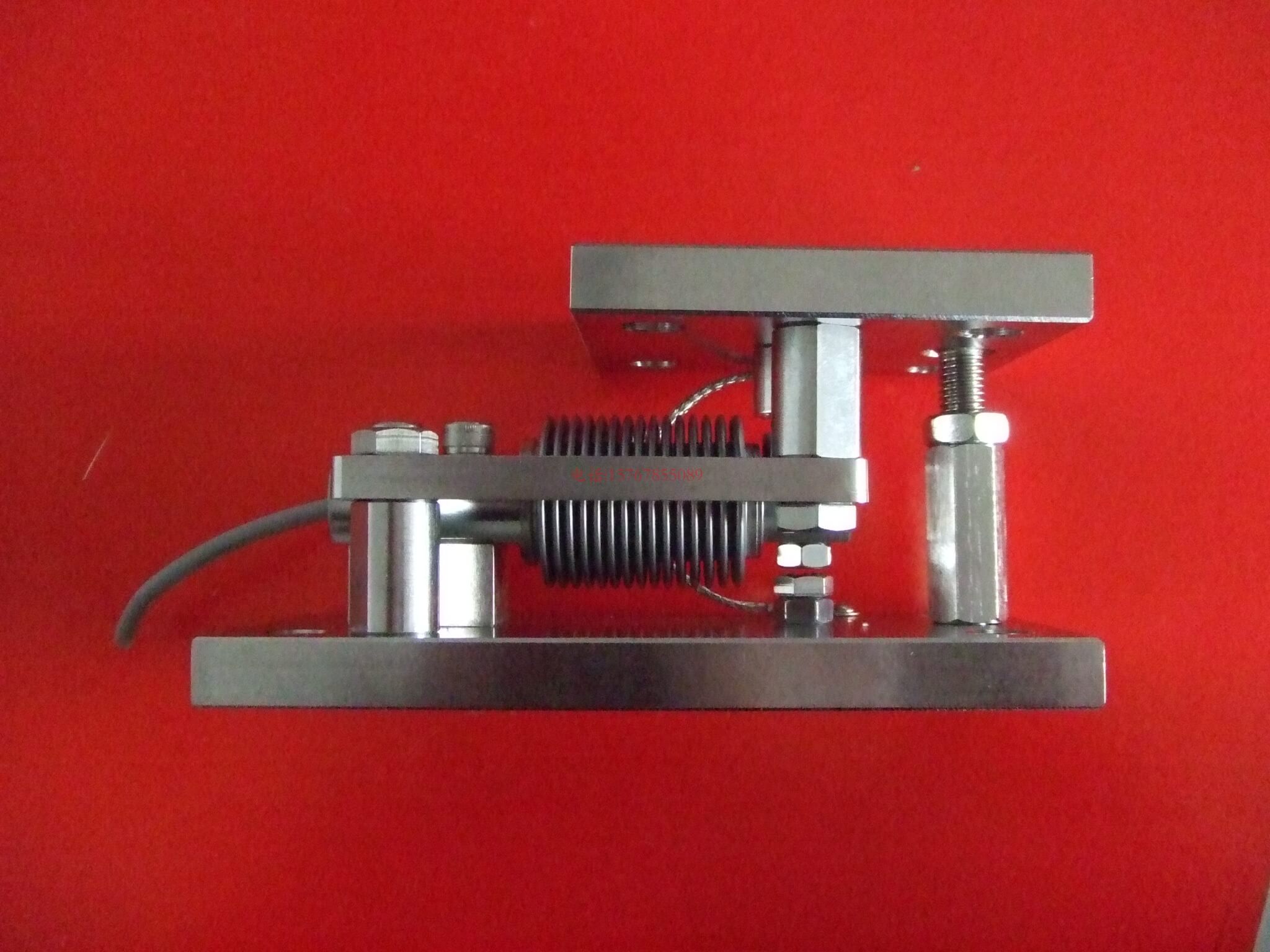

智能称重传感器是包装和分选设备以及自动检重秤的核心。采用 德国HBM FIT7A 数字称重传感器,可确保您的动态称重系统能够发挥最大潜力:

FIT7A 称重传感器对您的设备来说不仅仅是传感器,实际上更是您开发过程中的“创新引擎”。极具吸 引力的价格和优异的技术性能可以帮助您设计出新一代的自动检重秤和包装系统。从而开辟新的细分市场。让你在全球竞争中占据领先地位。

用于自动检重秤

结构结实,信号响应快,滤波时间短,提高检重秤生产量

不锈钢外壳,可使用洗涤剂清洗,用于食品工业

内置仪表和温度补偿,即时在温度变化情况下也具有极高的精度。

结实可靠

十倍过载能力,极为稳定可靠

优异的偏心补偿能力,称台可长达 600 mm

IP66 保护等级,可使用清洗剂冲洗

可使用插头替代电缆: 便于紧急处理突发状况

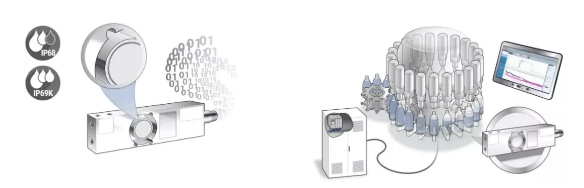

智能

FIT7A 可单机使用,无需 PLC 即可对机构进行控制

久经验证的滤波器,能消除来自输送装置的干扰

免费 PanelX 软件,减少开发时间并可对检重秤进行优化

| Type | FIT7A | |||||||||||||||||||||

| Accuracy class 1) | C3 | |||||||||||||||||||||

| Number of load cell verification intervals | nLC | 3000 | ||||||||||||||||||||

| Fraction | Plc | 0.8 | ||||||||||||||||||||

| Maximum capacity | Emax | kg | 3 | 5 | 10 | 20 | 30 | 50 | 75 | |||||||||||||

| Minimum load cell verification interval (standard and option 6 = VA) | vmin | g | 0.5 | 1 | 2 | 5 | 10 | |||||||||||||||

| Maximum scale interval factor Y (standard and option 6 = VA) | Y | 6000 | 10,000 | 6000 | 10,000 | 7500 | ||||||||||||||||

| Temperature coefficient of the zero signal per 10 K (standard and option 6 = VA) | TC0 | % of Cn |

土0.0266 | 土0.0160 | 土0.0266 | 土0.0160 | 土0.0213 | |||||||||||||||

| Maximum platform size (L x W) | mm | 400 x 400 | 600 x 500 | |||||||||||||||||||

| Nominal (rated) sensitivity | Cn | digit | 1,000,000 | |||||||||||||||||||

| Zero signal | 0 土100,000 | |||||||||||||||||||||

| Temperature coefficient of the sensitivity per 10 K 3) in the temperature range +20 ¼ +40°C −10 ¼ +20°C |

TCS | % of Cn |

土0.0200 土0.0133 | |||||||||||||||||||

| Non‐linearity 3) | dlin | 土0.0166 | ||||||||||||||||||||

| Relative reversibility error 3) | dhy | 土0.0166 | ||||||||||||||||||||

| Minimum dead load output return | MDLOR | 土0.0166 | ||||||||||||||||||||

| Off‐load error 2) | 土0.0166 | |||||||||||||||||||||

| Nominal (rated) ambient temperature range | BT | °C | -10 ¼ +40 | |||||||||||||||||||

| Operating temperature range | Btu | -10 ¼ +50 | ||||||||||||||||||||

| Storage temperature range | Btl | -10 ¼ +70 | ||||||||||||||||||||

| Limit load at 20 mm eccentricity | EL | % of Emax |

1000 | |||||||||||||||||||

| Service load at centric load input | 150 | |||||||||||||||||||||

| Relative vibrational stress at max. 50 mm eccentricity | Fsrel | 70 | ||||||||||||||||||||

| Nominal (rated) displacement 4) | snom | mm | <0.1 | |||||||||||||||||||

| Weight, approx. | m | kg | 3 | |||||||||||||||||||

| Degree of protection per DIN EN 60529 (IEC 529) | IP66 5) | |||||||||||||||||||||

| Voltage supply Operating voltage (DC) Power consumption Start‐up current |

UB | V W A | +10 ¼ +30 三2 <0.2 |

|||||||||||||||||||

| Material Housing Diaphragm Bonded seals Base plate |

Stainless steel 1.4545 6) Silicone rubber R830 Stainless steel 316L 7) Stainless steel 1.4301 6) | |||||||||||||||||||||

| 1) As per OIML R60, with PLC = 0.8. | ||||||||||||||||||||||

| 2) As per OIML R76. | ||||||||||||||||||||||

| 3) The values for non‐linearity (dlin), relative reversibility error (dhy) and temperature coefficient of sensitivity (TCS) are recommended val ues. The sum of these values is within the cumulated error limits according to OIML R60. | ||||||||||||||||||||||

| 4) Loading with Emax and center of gravity in center of platform. | ||||||||||||||||||||||

| 5) When vent hose is properly connected. | ||||||||||||||||||||||

| 6) As per EN 10088-1. | ||||||||||||||||||||||

| 7) Gaskets may need protecting against aggressive cleaning agents. | ||||||||||||||||||||||

| Type | FIT7A | |||||||||||||||||||||

| Accuracy class 1) | C4 | |||||||||||||||||||||

| Number of load cell verification intervals | nLC | 4000 | ||||||||||||||||||||

| Fraction | Plc | 0.8 | ||||||||||||||||||||

| Maximum capacity | Emax | kg | 3 | 5 | 10 | 20 | 30 | 50 | 75 | |||||||||||||

| Minimum load cell verification interval (standard and option 6 = VA) | vmin | g | 0.5 | 1 | 2 | 5 | 10 | |||||||||||||||

| Maximum scale interval factor Y (standard and option 6 = VA) | Y | 6000 | 10,000 | 6000 | 10,000 | 7500 | ||||||||||||||||

| Temperature coefficient of the zero signal per 10 K (standard and option 6 = VA) | TC0 | % of Cn |

土0.0266 | 土0.0160 | 土0.0266 | 土0.0160 | 土0.0213 | |||||||||||||||

| Maximum platform size (L x W) | mm | 400 x 400 | 600 x 500 | |||||||||||||||||||

| Nominal (rated) sensitivity | Cn | digit | 1,000,000 | |||||||||||||||||||

| Zero signal | 0 土100,000 | |||||||||||||||||||||

| Temperature coefficient of the sensitivity per 10 K 2)3) in the temperature range +20 ¼ +40°C −10 ¼ +20°C |

TCS | % of Cn |

土0.0149 土0.0100 | |||||||||||||||||||

| Non‐linearity 3) | dlin | 土0.0125 | ||||||||||||||||||||

| Relative reversibility error 3) | dhy | 土0.0125 | ||||||||||||||||||||

| Minimum dead load output return | MDLOR | 土0.0125 | ||||||||||||||||||||

| Off‐center load error 2) | 土0.0125 | |||||||||||||||||||||

| Nominal (rated) ambient temperature range | BT | °C | -10 ¼ +40 | |||||||||||||||||||

| Operating temperature range | Btu | -10 ¼ +50 | ||||||||||||||||||||

| Storage temperature range | Btl | -25 ¼ +70 | ||||||||||||||||||||

| Limit load at 20 mm eccentricity | EL | % of Emax |

1000 | |||||||||||||||||||

| Service load at centric load input | 150 | |||||||||||||||||||||

| Relative vibrational stress at max. 50 mm eccentricity | Fsrel | 70 | ||||||||||||||||||||

| Nominal (rated) displacement 4) | snom | mm | <0.1 | |||||||||||||||||||

| Weight, approx. | m | kg | 3 | |||||||||||||||||||

| Degree of protection per DIN EN 60529 (IEC 529) | IP66 5) | |||||||||||||||||||||

| Voltage supply Operating voltage (DC) Power consumption Start‐up current |

UB | V W A | +10 ¼ +30 三2 <0.2 |

|||||||||||||||||||

| Material Housing Diaphragm Bonded seals Base plate |

Stainless steel 1.4545 6) Silicone rubber R830 Stainless steel 316L 7) Stainless steel 1.4301 6) | |||||||||||||||||||||

| 1) As per OIML R60, with PLC = 0.8. | ||||||||||||||||||||||

| 2) As per OIML R76. | ||||||||||||||||||||||

| 3) The values for non‐linearity (dlin), relative reversibility error (dhy) and temperature coefficient of sensitivity (TCS) are recommended val ues. The sum of these values is within the cumulated error limits according to OIML R60. | ||||||||||||||||||||||

| 4) Loading with Emax and center of gravity in center of platform. | ||||||||||||||||||||||

| 5) When vent hose is properly connected. | ||||||||||||||||||||||

| 6) As per EN 10088-1. | ||||||||||||||||||||||

| 7) Gaskets may need protecting against aggressive cleaning agents. | ||||||||||||||||||||||

| Type | FIT7A | |||||||||||||||||||||

| Measurement signal resolution | bit | 24 | ||||||||||||||||||||

| Data rate | 1/s | 4 ¼ 1200 | ||||||||||||||||||||

| Digital filter bandwidth | Hz | 0 ¼ 120 | ||||||||||||||||||||

| RS-485 interface baud rates | baud | 1200/2400/4800/9600/19200/38400/57600/115200 | ||||||||||||||||||||

| Maximum number of bus nodes | 90 | |||||||||||||||||||||

| CANopen interface (CANopen/DeviceNet) Baud rate Maximum cable length |

baud m | Standard CiA DS301 10000 ¼ 1000000 三5000 (10 kBaud) ¼ 三100 (500 kBaud) ¼ 三25 (1 MBaud) |

||||||||||||||||||||

| DeviceNet Baud rate Maximum cable length |

baud m | Release 2.0 DVA 125000 ¼ 500000 三5000 (10 kBaud) ¼ 三100 (500 kBaud) |

||||||||||||||||||||

| Diagnostics bus RS‐485 2‐wire (extended version E) | baud | 38400 | ||||||||||||||||||||

| Baud rate | ||||||||||||||||||||||

| Maximum cable length | m | 500 | ||||||||||||||||||||

| Asynchronous interface RS‐485 4‐wire (socket 1) | baud | 1200/2400/4800/9600/19200/38400/57600/115200 | ||||||||||||||||||||

| Baud rate | ||||||||||||||||||||||

| Maximum cable length | m | 500 | ||||||||||||||||||||

| Trigger input (socket 1) | V | 0 ¼ +12 | ||||||||||||||||||||

| Input voltage | ||||||||||||||||||||||

| Low level | V | <1 | ||||||||||||||||||||

| High level | V | >4 | ||||||||||||||||||||

| Input resistance | kΩ | 70 | ||||||||||||||||||||

| Control inputs (extended version E, socket 2) 1) | V | 0 ¼ +30 | ||||||||||||||||||||

| Input voltage | ||||||||||||||||||||||

| Low level | V | <6 | ||||||||||||||||||||

| High level | V | >10 | ||||||||||||||||||||

| Input resistance | kΩ | 9 | ||||||||||||||||||||

| Control outputs (extended version E, socket 2) 1) | V A A | +11 ¼ +30 <0.5 <1 |

||||||||||||||||||||

| External supply voltage Max. current per output Max. total current of all outputs |

||||||||||||||||||||||

| 1) The signals apply to GND of socket 1. | ||||||||||||||||||||||

下面这些产品,一样很精彩哟!

产品繁多,总有一款适合你,更可来图来样定制生产,选型!

PW27A 称重传感器额定量程为10kg 和 20kg ,符合严苛的 EHEDG 卫生规范,因此非常适合于食品和药品地灌装、包装及称重。 采用不锈钢测量体和坚固的不...

高性能 WTX110-A 称重终端带有坚固的不锈钢外壳,并通过IP69K认证。适用于各种静态或动态灌装或配量任务。 是恶劣环境下或有严格卫生要求的贸易称重重应...

PW25P Single point load cell for harsh environments。 Special features Nominal load 10 kg, 20 kg Stainless steel High ration of min...

PW25卫生型称重传感器精度等级C3,采用SP4 “印记”标准尺寸,通常用于配料、多头组合秤等称重任务。保护等级高达IP69K的PW25称重传感器紧致密封,内部集成...

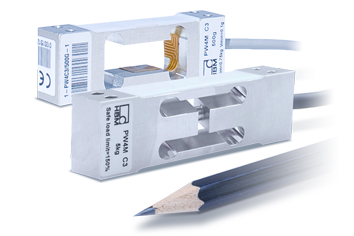

PW4M单点式称重传感器 特点用于测定小质量(0.3 kg…3 kg) 铝合金材质 偏心负载补偿 连接电缆屏蔽 PW4M… Single point load cells Specia...

微型PW4M和PW4M-OP单点称重传感器最大额定量程为5千克。其具有极高的测量精度和性价比。这些称重传感器可用于贸易秤应用,并且具有极高的精度(精度等...

贸易秤用称重传感器 Z6R 额定量程 20 到 200 kg,并与 HBM 久经验证的 Z6 称重传感器完全兼容。即使在卫生要求高或恶劣环境下应用,Z6R 称重传感器表现也...

PW15iA:第一个SP4“印记”数字称重传感器 易于安装,开发速度快:SP4“印记”简化了称重系统的结构—现在推出了数字化型号 HBM的SP4称重传感器已经成为平台...

产品名称:Z7AC3/5T称重传感器 产品品牌:德国HBM称重传感器,HBM称重传感器 产品价格:在线询价 产品特点: 臂悬梁式传感器 ...

产品名称:Z7AC3/2T称重传感器 产品品牌:德国HBM称重传感器,HBM称重传感器 产品价格:在线询价 产品特点: 臂悬梁式传感器 ...

产品名称:Z6/M称重模块 产品品牌:德国HBM称重模块,HBM称重模块 产品价格:在线询价 产品特点: 选用Z6FD1或Z6FC3称重传感器 OIML R60认证 ...

产品名称:Z6FD1/200Kg,1-Z6FD1/200Kg-1 产品品牌:德国HBM称重传感器,HBM称重传感器 产品价格:在线询价 产品特点: 波纹管式称重传感器 ...

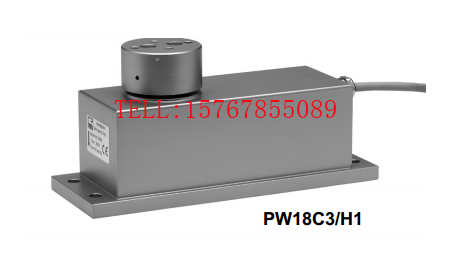

产品名称:PW18C3/50Kg称重传感器 产品品牌:德国HBM 称重传感器,HBM称重传感器 产品价格:在线询价 PW18C3/50Kg称重传感器产品特点: 高精...

产品名称:PW18C3/H1/75kg称重传感器 产品品牌:德国HBM 称重传感器,HBM称重传感器 产品价格:在线询价 产品特点: 集成垂直过载 高精度...

产品名称:Z6FD1/100Kg,1-Z6FD1/100Kg-1 产品品牌:德国HBM称重传感器,HBM称重传感器 产品价格:在线询价 产品特点: 波纹管式称重传感器 ...

以质量求生存,以信誉求发展,满足合同规定及潜在需求!

全国咨询热线

157-6785-5089