润滑油供料泵 气动柱塞泵 德派DOPAG

- 特别说明:产品图片以及参数跟实际产品略有差异。

- 采购说明:一切规格按照客户实际情况或考察后下单采购,支持非标定制。

- 库存配送:有货,全国送货保障!

- 温馨提示:本产品一经下单采购,非质量问题不支持退货!如产品质量问题,可三个月内免费退换货!

德派气动柱塞泵可集中供油或单工位供油,并且可将材料直接从材料桶中抽出,如润滑脂、粘合剂和密封剂或者硅胶、聚氨酯和环氧树脂等。

粘合剂和密封剂供料泵

德派的粘合剂供料泵系列可用于供给所有类型粘合剂,不论是低粘度还是高粘度。粘合剂供料泵可直接从带塞子的材料桶中抽出低粘度粘合剂,而配有压盘的柱塞泵可用于处理高粘度、不易流动的粘合剂。用于低粘度、易流动粘合剂的柱塞泵可通过材料桶的堵塞孔手动或者通过气动升降装置抽出。用于较高粘度产品的柱塞泵均为双柱塞,并配备压盘,紧紧贴合材料筒内侧,确保粘合剂在使用过程中不会受到污染。压盘还有助于清洁滚筒侧面,减少浪费。

德派的润滑脂供料泵系列设计用于直接从容量为1升和200升的敞口原装材料桶清洁地输出所有类型润滑脂。每个润滑脂泵均为双柱塞,并配有压盘,紧紧贴合材料筒内侧,确保润滑脂在使用过程中不会受到污染。压盘还有助于清洁滚筒侧面,减少润滑脂浪费。德派润滑脂供料泵尤其适用于为多个润滑脂定量系统集中供料或单工位供料。润滑脂泵可以成对使用,结合自动转换系统,使材料桶内的材料用完后时不会造成生产损失。

| 基本型 | P30-LL | P80-LL | P200-LL |

|---|---|---|---|

| 单手操作 | X | X | X |

| 双手安全操作 | X | X | X |

| 压力比 (驱动气缸10:1/100mm) |

10:1 / 30:1 | 10:1 / 30:1 | 10:1 / 30:1 |

| 流速(40次往复) l/min |

1.2 | 1.2 | 1.2 |

| 材料粘度 (单向工作泵/双向往复泵) |

0-2 /0-3 | 0-2 / 0-3 | 0-2 / 0-3 |

| 工作压力 (驱动气缸 63/100mm) bar |

10-60 / 30-180 | 10-60 / 30-180 | 10-60 / 30-180 |

| 耗气量 (驱动气缸63/100mm) l/min |

110 /270 | 110 / 270 | 110 / 270 |

| 底盘尺寸(A x B) mm |

600 x 550 | 600 x 550 | 900 x 600 |

| 未延伸高度 (C) mm |

997 | 1170 | 1440 |

| 最大延伸高度 (C) mm |

1481 | 1900 | 2450 |

| 最大材料桶高度 mm |

460 | 750 | 880 |

| 最大材料桶容积 l |

30 | 80 | 200 |

| 材料桶最大外径 Ø mm |

444 | 444 | 575 |

Drum pumps

DOPAG has completely reengineered its product range in the area of drum pumps suiting the needs of its customers specifically having grease application in mind. The DOPAG LUBRILINE drum pumps are featuring double acting ball valve or chop check pumps. They feed single component media such as greases and oils from NLGI0 to NLGI3 directly and clean from original containers. DOPAG drum pumps have prooved themselves useful as central material supply systems as well as supplying single stations. DOPAG drum pumps are manufactured as modular, robust and fail-safe, as well as remarkably service and maintenance friendly.

Product features

Technical data

| Basic version | P80/1H-LL | P80/2H-LL | P200/1H-LL | P200/2H-LL | |||||||||||||||||||||||||||

| 1-hand operation | X | X | |||||||||||||||||||||||||||||

| 2-hand security operation | X | X | |||||||||||||||||||||||||||||

| Pressure ratio (Drive) | 10:1 / 30:1 | 10:1 / 30:1 | 10:1 / 30:1 | 10:1 / 30:1 | |||||||||||||||||||||||||||

| Flow rate (at 40 double strokes) l/min | 1.2 | 1.2 | 1.2 | 1.2 | |||||||||||||||||||||||||||

| Material viscosity (Ball valve pump/Chop check pump) NLGI |

0–2 / 0–3 | 0–2 / 0–3 | 0–2 / 0–3 | 0–2 / 0–3 | |||||||||||||||||||||||||||

| Working pressure (Drive 10:1/30:1) bar | 10–60 / 30–180 | 10–60 / 30–180 | 10–60 / 30–180 | 10–60 / 30–180 | |||||||||||||||||||||||||||

| Air consumption at 40 double strokes (Drive 10:1/30:1) l/min |

110 / 270 | 110 / 270 | 110 / 270 | 110 / 270 | |||||||||||||||||||||||||||

| Dimensions base plate (A x B) mm | 600 x 550 | 600 x 550 | 900 x 600 | 900 x 600 | |||||||||||||||||||||||||||

| Height when lifter not extended (C) mm | 1170 | 1220 | 1440 | 1480 | |||||||||||||||||||||||||||

| Height when lifter extended (C) mm | 1900 | 1900 | 2450 | 2450 | |||||||||||||||||||||||||||

| Maximum container height mm | 750 | 750 | 880 | 880 | |||||||||||||||||||||||||||

| Maximum container size l | 80 | 80 | 200 | 200 | |||||||||||||||||||||||||||

| Maximum external Ø container mm | 444 | 444 | 575 | 575 | |||||||||||||||||||||||||||

Tandem versions

All configurations can be extended to a tandem version for interruption free production.

Modules

Options

Product ID code

The modularity of the new drum pump range enables a great number of combinations. DOPAG has developed an easy to use product ID code to be able to create pump configurations just within minutes.By knowing the material characteristics it will be possible to choose the right modules and if required additional options. This ID code can be used to order your customised pump or just as a request for quotation. Let us know your required configuration?

Material pressure regulators with piston

Material pressure regulators reduce the pressure of the delivered material to the required working pressure. Apart from reducing pressure (main function), these valves compensate the pulsations which occur during the material delivery with piston pumps due to the changeover position of the pump.

Such pulsations would cause a short-time drop of pressure and lead to a slight reduction of the material flow. In case of small metering quantities, this might impair product quality as especially for such applications an absolutely consistent material flow must be ensured.

Product features

1 Pre-stressing nut

2 Spring assembly

3 Lock nut

4 Piston

5 Material outlet / pressure gauge connection

6 Valve seat

7 Ball

8 Compression spring

9 Filter element, 30 mesh

10 Material inlet / pressure gauge connection

下面这些产品,一样很精彩哟!

产品繁多,总有一款适合你,更可来图来样定制生产,选型!

德派DOPAG之前的LSR混合单元需要相对复杂的准备、安装及调试流程,需要花费较多的时间及人力,我们全新研发的混合单元解决了这个问题。全新的设...

Silcomix PE200是紧凑型设计、电控驱动柱塞泵定量混胶系统,用于连续处理中高粘度的硅胶材料,混合比例可达100:100,材料可从20L至200L的原料桶中直接抽...

Ladomix是紧凑型移动式定量涂胶及混胶系统,有齿轮泵或柱塞泵可选。Ladomix G-SF为齿轮定量系统;Ladomix P-SF为柱塞计量系统。二者均可用于处理混...

齿轮泵是所有齿轮系统的核心。齿轮泵基于阿基米德原理,由于不需要任何控制元件,因此不同于其他输送和定量系统。这意味着,不论是输送过程本身,还是确...

Gelcomix齿轮泵定量系统是结构紧凑、无需溶剂、齿轮泵驱动的定量涂胶及混胶系统。此系统用于处理低至中粘度多组份材料,如聚氨酯或环氧树脂等,使用压力...

eldomix 100、600是无需溶剂、紧凑型齿轮定量及混胶系统,能够处理各种低到中粘度多组份材料,如环氧树脂、聚氨酯或聚硅酮,通过材料压力罐供料。也可以...

双组份材料,如环氧树脂、聚氨酯和硅胶。根据应用或要求的不同,选择柱塞泵或齿轮泵系统。既可以选择基本配置的模块化设计,也可根据客户需求选择客户化配置...

德派柱塞式定量涂胶及混胶系统可根据客户的不同需求提供模块化或定制化的解决方案。 vectodis柱塞式定量系统 Vectodis用于处理单组份材料。只需配置定...

齿轮泵是所有齿轮系统的核心。齿轮泵基于阿基米德原理,由于不需要任何控制元件,因此不同于其他输送和定量系统。这意味着,不论是输送过程本身,还是确定输...

德派 DOPAG微型流量传感器是流量监测装置,用于半自动或全自动计量流程,以探测材料是否根据设定的流量输出。微型流量传感器并不用于控制流量。它...

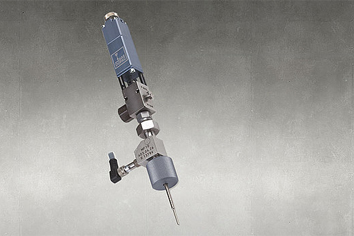

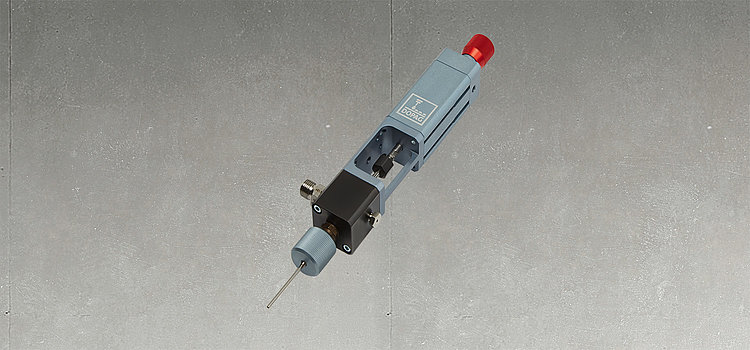

德派 DOPAG针式计量阀用于处理各种低到高粘度介质。阀体包括两个独立隔开的部分。这种独立设计的优势在于材料不会进入驱动气缸中影响阀针的移动。阀针采用特...

填充:当下端气源接口注入压缩空气时,阀门位于其初始位置。控制阀中的阀针位于上部位置,从而关闭出油口。材料到计量腔的通道开启后,给予材料一定的压...

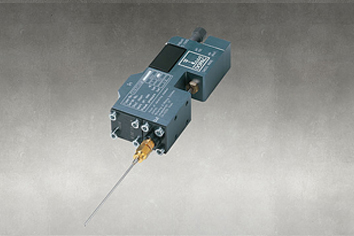

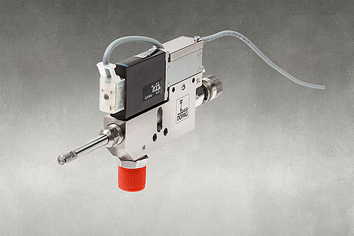

德派定量阀可以应用于众多行业,处理从低至高粘度材料,尤其适用于对精度和重复精度要求较高的应用领域。德派定量阀有多种不同系列及尺寸可供客户选择,选择...

德派DOPAG喷雾阀专门用于涂覆润滑脂和润滑油。该阀可用于间歇喷雾和连接喷雾。喷雾阀的特别之处是集成了喷气阀,用于在胶水、油脂等材料喷射后使用...

喷射阀是一种可以快速切换的阀门。提供长喷嘴和短喷嘴。根据喷嘴的大小,可涂覆各种粘度的材料。通过一个集成5/2路电磁阀控制。气动部分内部距离很...

以质量求生存,以信誉求发展,满足合同规定及潜在需求!

全国咨询热线

157-6785-5089